Agricultural Oxide

£34.50 – £78.00Price range: £34.50 through £78.00 ex VAT

Agricultural Oxide – A long oil based protective metal coating, suitable for all types of interior/exterior substrates. It has excellent covering power and can be used on block work, steel sheets, asbestos sheeting as well as wood. It has a good gloss finish, gives protection against weathering and corrosion.

BULK ORDERS? CALL 01782 550733 FOR DISCOUNTS!

Available Metal Paint Colours

*The colours of metal paints shown in this chart are approximate and may vary.

Agricultural Oxide – Product Description & Recommended Use

- A single-pack, quick-air-drying enamel topcoat with a tough, sheen finish.

- Made from high-quality synthetic resins and is lead and chrome-free.

- An easy to apply metal paint by airless spray, conventional spray or roller and brush.

- Suitable for direct-to-metal applications.

- Suitable for application to steel and non-ferrous metal, and heavy-duty industrial use.

- For higher temperatures, we recommend thin films to reduce the risk of thermal-shock cracks of the paint-film during heating and cooling cycles.

Agricultural Oxide – Reviews and Feedback

Leave a review

Read our customer reviews

Buyer: Bridget Fellows

Product: Agriculture Oxide

Date: 23 Feb 2019

Rating: 9/10

Very good product, great prompt service – would recommend this company.

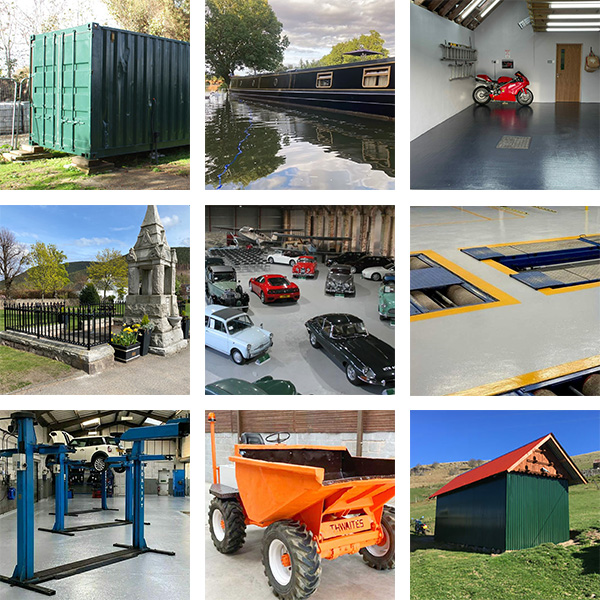

Send us your photos...

We are always interested in seeing the finished job when we send out paints to our customers. Whether you have completed a domestic garage or a warehouse, it is always great to see "before and after" images showing what our products can do. If you have the time, please send out your photos (and anything else you would like to tell us about the project) to sales@regalpaints.co.uk. We would love to feature your projects on our website!

Regal Paint® - Metal Paint Manufacturers

Regal Paints® manufacture high performance metal paint for a range of industrial and commercial applications. These specialist paints include our two pack epoxy metal paints as well as our single pack metal paints like Aluminium Quick Dry Enamel, Decorative Gloss, One Coat Steel Enamel, Quick Drying Gloss Enamel, and Skip and Container paint. Our paints are also available in a versatile range of colours, including old favourites like red oxide primer and red oxide paint as we well as modern staples like black metal paint and grey metal paint. All of the Regal range of metal primers and topcoats are formulated to provide the very best possible protection on a wide range of substrates. We continue to supply our paints to many new and long-standing customers in the engineering, agricultural, construction and trade sectors and are able to formulate and supply bespoke solutions and manufacture to your RAL (quantity dependent). In addition to our range of metal paint products, Regal Paints provide a comprehensive selection of floor paint, masonry paint and timber paint as well as paints for specialist applications.

| Weight | N/A |

|---|---|

| Select Colour |

Brunswick Green ,Ford Tractor Blue ,Cornflower Blue ,Red Oxide ,Post Office Red ,Caterpillar Yellow ,JCB Yellow ,Chocolate Brown ,Bright Orange ,Slate Grey ,Light Grey ,Black ,White |

| Select Size |

5 Litres ,20 Litres |

FAQs

FAQ High Build Phosphate Quick Dry Primer

Over the years there has been a lot of misinformation provided concerning red oxide, primarily due to its widespread use in red oxide primers where its principal application is to camouflage rust creeping through from the steel underneath. Red oxide is actually the common name for iron III oxide (Fe203) which in colour and chemically is very similar to the hydrated iron oxide (rust) which hides any early signs of rust. Red iron oxide when purified and sold as a pigment for use in paint and ceramics has the advantage of being stable having already oxidised and so resistant to further oxidation and heat changes at most temperature found in common applications. It is also hard and very resistant to mechanical damage. All of these characteristics have led to its widespread use in primer paints or direct to metal paints for iron and steel for many decades. However, unless combined with an active pigment, usually a phosphate to protect the steel there is little actual protection provided by the red iron oxide other than as barrier and here it is often confused with a more effective form of barrier coating based in micaceous iron oxide which is another form entirely and uses its lamellar plate like structure to provide some physical barrier to the penetration of water and oxygen, both of these are needed for corrosion to take place.

Corrosion is an electrochemical process, very much like a battery in which the iron in steel is oxidised by losing electrons to become positively charged iron ions:

Fe » Fe2+ + 2e-

The electrons produced by this reaction combine with hydrogen ions in the water as well as with dissolved oxygen to produce water:

The formation of rust requires iron, water and oxygen. Although it’s a complex process, the chemical equation is simply:

4Fe + 3O2 + 6H2O → 4Fe(OH)3.

The First Step: Oxidation of Solid Iron

It’s common knowledge that rust occurs when you leave water on a metal implement or you leave it exposed to moist air. That’s because the first step in the rusting process involves the dissolution of solid iron into solution. The formula for this is:

Fe(s) → Fe2+(aq) + 2e-

The electrons produced by this reaction combine with hydrogen ions in the water as well as with dissolved oxygen to produce water:

4e- + 4H+(aq) + O2(aq) → 2H2O(l)

The consumption of hydrogen ions that occurs as iron dissolves leaves a preponderance of hydroxide (OH-) ions in the water. The iron(II) ions react with them to form green rust:

Fe2+(aq) + 2OH–(aq) → Fe(OH)2(s)

BUT that isn’t the end of the story. The iron(II) ions also combine with hydrogen and oxygen in the water to produce iron(III) ions:

4Fe2+(aq) + 4H+(aq) + O2(aq) → 4Fe3+(aq) + 2H2O(l)

These iron ions are the source of the reddish deposit that gradually eats holes in all corroding steel and iron from car bodywork to metal roofing to farm ironwork. They combine with the extra hydroxide ions to form iron(III) hydroxide:

Fe3+(aq) + 3OH–(aq) → Fe(OH)3

This compound dehydrates to become Fe2O3.H2O, which is the chemical formula for rust. Note how similar it is t the chemical formula for Red iron oxide pigment Fe2O3 and this is why red iron oxide paints help to camouflage but do not prevent corrosion when used as red iron oxide primers or paints – for that you need a pigment that actively prevents corrosion such as Nanoguard ACP

Anti corrosive pigments? What are they? Here we try to give a simple explanation.

Over the years, many products have been used (to a greater or lesser degree of success) in the prevention of corrosion, often together with red oxide to produce a red oxide metal primer.

The purpose of primer paints is to act as preparation, forming part of the protective coating for the underlying metal and inhibiting rust formation.

In the past, toxic pigments such as red lead, and carcinogenic pigments such as chromates, have been used. However, due to health concerns they were replaced largely by zinc phosphate. In turn, this old technology was found to be very bad for the environment leading to its replacement by zinc-free systems, replacing the harmful heavy metal zinc with the friendly metal calcium. Since calcium phosphates are widely found in our bodies there are no harmful effects on either human health or the environment from this technology and so modern formulations tend to be zinc-free.

Early versions of zinc-free anti-corrosives first appeared in the late 1980’s when BP became concerned about the leaching of heavy metals and things like zinc-based paints into the sea from their oil rigs. This earlier technology, based on calcium ion exchanged silica, has gradually been superseded by a variety of calcium-phosphate based products such as Nanoguard ACP DCP and Nanoguard ACP2 (used to replace carcinogenic chromates).

Formulation of metal protection products, including direct-to-metal products such as the traditional hammer-finish paints and epoxy coatings, now widely use calcium-phosphate to protect metalwork. With a pedigree developed for the harsh environment of the North Sea oil fields these zinc-free phosphates continue to provide longevity to steel structures around the world without damaging the environment or our health.

Here at Industrial Protective Paints Ltd, all of our products that require anticorrosive properties, for example Regal Anticorrosive Primers and Regal Skip and Container Paint, are manufactured using calcium-phosphate technology.

FAQ Skip and Container Paint

If you are painting bare metal, we would always recommend the use of an undercoat or primer coat first. Regal Skip and Container Paint is made with extra anticorrosive materials, more than regular metal enamel so does give more corrosion protection. This is designed for quickly overspraying existing skip paint or container paint as we know our customers need a speedy turnaround. Our primer paint is designed for bare metal or spot priming, creating an anchor between the metal and the metal paint. So yes, ideally use our red oxide primer or grey oxide primer to undercoat bare metal. Always prepare the surface thoroughly prior to painting.

Regal Skip and Container Paint is manufactured with the addition of calcium phosphate. This gives added protection against metal corrosion. Regal Quick Drying Gloss Enamel doesn’t contain calcium phosphate and is a topcoat enamel.

The Skip and Container Paint can be used alone as an overspray to tidy up painted skips and containers. If used in combination with Regal Anticorrosive Phosphate Primer, there will be an additional level of protection.

Always try to remove rust prior to painting and spot prime if needed.

We make our Skip and Container Paint on a xylene thinner. If you do need to thin back the paint, you can use a standard cellulose thinner. Please do not under any circumstance use a white spirit. Cellulose thinner is a standard thinner for paint and can be found in most DIY stores such as B&Q. We do sell standard cellulose thinner in both 5 litre and 25 litre options – if you would like to add some to your order, please call us on 01782 550733.

Skip Paint is manufactured with the customer in mind. Understanding our market is key and it was in fact Regal Paint who spotted the gap for a product called Skip and Container Paint. In the days BI (Before Internet) we would advertise to skip companies through the paper copy of Industrial Exchange and Mart, selling red oxide primer and onecoat enamel. Realising that speed is of the essence, we started to make a specific product combining the anticorrosive properties of primer with the durability of enamel. Use our skip paint to freshen up the inside or outside of regular skips, enclosed bins, roll on roll off skip containers and to also paint shipping containers. Durable, quick-drying, full of anticorrosive properties, and easy to apply. Regal Skip and Container Paint is the original and the best.

Floor Paint FAQs

Whilst newly laid concrete slab can look dry and it can also feel dry to touch, it may actually still contain water. We would recommend that you wait to paint new concrete until it has dried for 1 month per 1-inch depth of the concrete slab. So, for a newly laid concrete block of 6 inches in depth, we would recommend waiting for at least 6 months until painting.

WE AIM TO DISPATCH ORDERS RECEIVED PRE-NOON ON THE SAME DAY (STOCK DEPENDENT)

ALL ORDERS SENT ON A NEXT WORKING-DAY SERVICE

FREE DELIVERY ON ALL ORDERS OVER £300*

*£300 NET. Excludes surcharge areas - delivery surcharge will still apply.

Epoxy Primer

Epoxy Primer

Anticorrosive High Build Phosphate Quick Dry Primer

Anticorrosive High Build Phosphate Quick Dry Primer

Red Oxide Primer and Paint

Red Oxide Primer and Paint

Agriculture Oxide (Barn Paint)

Agriculture Oxide (Barn Paint)

Aluminium Quick Dry Enamel

Aluminium Quick Dry Enamel

Decorative Gloss

Decorative Gloss

One Coat Steel Enamel

One Coat Steel Enamel

Quick Drying Gloss Enamel

Quick Drying Gloss Enamel

Skip Paint / Container Paint

Skip Paint / Container Paint

Brunswick Green Metal Paints

Brunswick Green Metal Paints

Ford Tractor Blue Metal Paints

Ford Tractor Blue Metal Paints

Cornflower Blue Metal Paints

Cornflower Blue Metal Paints

Red Oxide Metal Paints

Red Oxide Metal Paints

Post Office Red Metal Paints

Post Office Red Metal Paints

Caterpillar Yellow Metal Paints

Caterpillar Yellow Metal Paints

JCB Yellow Metal Paints

JCB Yellow Metal Paints

Chocolate Brown Metal Paints

Chocolate Brown Metal Paints

Bright Orange Metal Paints

Bright Orange Metal Paints

Slate Grey Metal Paints

Slate Grey Metal Paints

Light Grey Metal Paints

Light Grey Metal Paints

White Metal Paints

White Metal Paints

Black Metal Paints

Black Metal Paints

Disposable Paint Brushes

Disposable Paint Brushes

Standard Paint Brushes

Standard Paint Brushes

Floor Roller Sleeves

Floor Roller Sleeves

Floor Roller Frames

Floor Roller Frames

Spiked Overshoes

Spiked Overshoes

Mixer Paddles

Mixer Paddles

Anti-Slip Additives

Anti-Slip Additives

Basement Floor Paint

Basement Floor Paint

Barn Paint

Barn Paint

Catteries Paint

Catteries Paint

Car Park Paint

Car Park Paint

Commercial Kitchen Paint

Commercial Kitchen Paint

Concrete Floor Paint

Concrete Floor Paint

Corridor Paint

Corridor Paint

Corrugated Iron Paint

Corrugated Iron Paint

Dog Kennel Floor Paint

Dog Kennel Floor Paint

Gallery Floor Paint

Gallery Floor Paint

Garage Floor Paint

Garage Floor Paint

Heavy Traffic Area Paint

Heavy Traffic Area Paint

Hospitals Paint

Hospitals Paint

Laundry Room Paint

Laundry Room Paint

Line Marking Paint

Line Marking Paint

Machinery Paint

Machinery Paint

Mezzanine Floor Paint

Mezzanine Floor Paint

Museums Paint

Museums Paint

Oil Rigs Paint

Oil Rigs Paint

Parlour Paint

Parlour Paint

Plywood Paint / MDF Paint

Plywood Paint / MDF Paint

Restaurant Paint

Restaurant Paint

Shop Floor Paint

Shop Floor Paint

Shipping Containers Paint

Shipping Containers Paint

Skip Paint / Container Paint

Skip Paint / Container Paint

Stable Paint

Stable Paint

Stadium Floor Paint

Stadium Floor Paint

Steel Bridge Paint

Steel Bridge Paint

Storage Room Paint

Storage Room Paint

Studio Floor Paint

Studio Floor Paint

Tractors Paint

Tractors Paint

Trailer Paint

Trailer Paint

Warehouse Floor Paint

Warehouse Floor Paint

Walkways Paint

Walkways Paint